Quality Assurance

DS Electronics regularly invests in new equipment so that we can consistently manufacture our customers’ products to the highest quality. Between our test engineering services and post-solder inspections, you can expect to receive a final product that is reliably free of defects.

We Have the Best Equipment for Delivering High-End Products

We have made significant investments in our equipment and capabilities that ensure efficient and repeatable manufacturing. Our wide selection of equipment allows us to deliver premium products to our customers around the world on time.

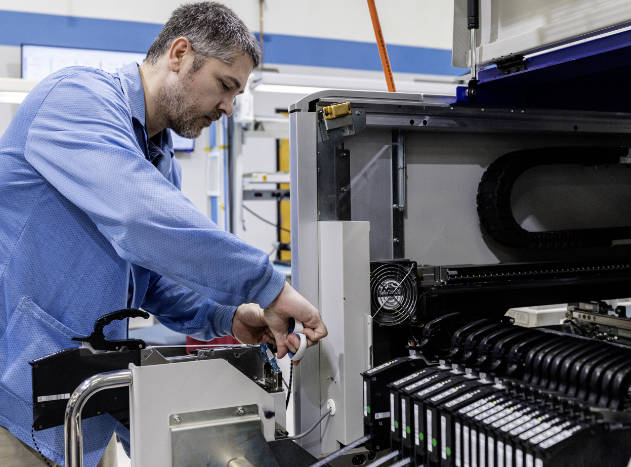

Pick and Place Machines

During production, our pick and place machines can repeatedly and accurately place small components like 0201 or fine-pitch devices like BGA’s with hundreds of hidden pins. Each machine’s software program has been optimized for speed and accuracy so that we can guarantee that production is completed on time.

Reflow Ovens

DS Electronics is a leader in PCB assembly because we produce exceptional products. We have multiple reflow ovens to ensure your boards have high-quality solder joints. We customize the perfect reflow recipe for each product that goes through the oven to create better quality solder joints. Strengthening solder joints allows us to deliver longer-lasting and better-performing products.

We expertly design reflow profiles based on the material, thickness, mass of the components, and the type of solder or flux that the assembly of your product requires. We will develop the perfect thermal profile by varying 10 different temperature zones, zone pressures, and belt speeds to ensure durable solder joints. Before we run a new assembly through the oven, we use a KIC profiler to validate the profile we have created and make sure it’s the right fit for your product.

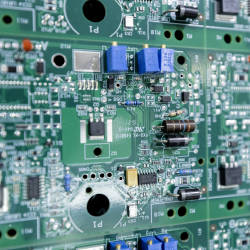

Inspection Machines

Producing reliable final products also requires putting them through a rigorous inspection. We have two top-of-the-line 3D automated optical inspection (AOI) machines and one 2D AOI machine available to examine your products after reflow. These machines repeatedly inspect each solder joint, component values, component placements, incorrect components, and more to verify that your product has been manufactured correctly.

Automating inspection makes the manufacturing process much more repeatable than manually inspecting PCBs. Using multiple AOI machines allows us to increase our throughput so that we can meet your high-volume demands by inspecting products at a faster rate. However, for smaller builds where it isn’t cost-effective to create a new recipe, we have an IPC-certified quality control inspector examine your product under a microscope to ensure you receive a high-quality product.

Solder Machines

In order to achieve repeatable soldering for your product’s through-hole components, we have invested in two robotic selective solder machines and a wave solder machine. Selective soldering allows us to efficiently move your product through production—mostly removing the extra production step of masking that wave solder typically requires.The programmed repeatable soldering process guarantees the first product off the line to be the same premium quality as the last.

SCHEDULE A TOUR

As a second-generation family-owned and operated company in Gilbert, AZ, ensuring that your products are built to the highest standards is of the utmost importance to us at DS Electronics. Call 480-967-5080 today to schedule a tour of our facility and learn more about our wide array of manufacturing equipment.